Ansys Sherlock

Ansys Sherlock automated design analysis software is the only Reliability Physics/Physics of Failure (PoF)-based electronics design analysis software that provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early design stages. Approximately 73% of product development costs are spent on the test-fail-fix-repeat cycle. Sherlock accelerates this process by empowering designers to accurately model silicon–metal layers, semiconductor packaging, printed circuit boards (PCBs) and assemblies to predict solder fatigue failures due to thermal, mechanical and manufacturing conditions. This helps eliminate test failures and design flaws, accelerate product qualification and introduce groundbreaking technologies.

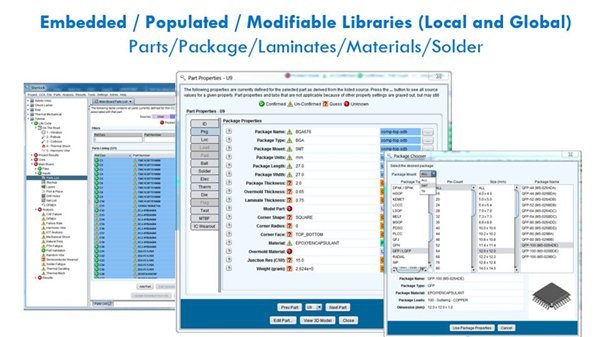

A unique, powerful capability of Sherlock is its revolutionary ability to rapidly convert electronic CAD (ECAD) files into CFD and FEA models with accurate geometries and material properties. Through its powerful parsing engine (capable of importing Gerber, ODB and IPC2581 files, etc.) and embedded libraries containing over 500,000 parts, Sherlock reduces pre-processing time from days to minutes and automates workflows through its integration with Ansys Icepak, Ansys Mechanical and Ansys Workbench.

In post-processing simulation results from Icepak and Mechanical, Sherlock is able to predict test success, estimate warranty return rates and make Icepak and Mechanical users more efficient by directly connecting simulation to material and manufacturing costs.

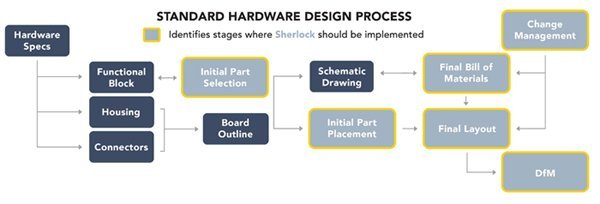

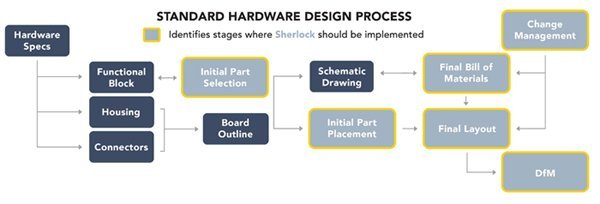

Sherlock can be used at every step in the hardware design process and is most valuable when implemented in the early design stages.

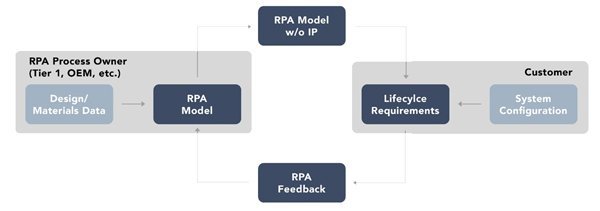

Additionally, Sherlock’s Locked IP Model protects intellectual property in the supply chain. With the Locked IP Model, you can transfer designs between design suppliers and design users while preserving PCB design details; the intended use of the PCB design will not be disclosed via environmental conditions or reliability requirements. This communication tool enables two entities to work together on a system with a layer of trust built into the reliability calculations.

Sherlock simplifies and improves reliability prediction using a unique, three-phase process consisting of data input, analysis, and reporting and recommendations.

Data Input

With its extensive parts/materials libraries, Sherlock automatically identifies your files and imports your parts list, then builds an FEA model of your circuit board in minutes by:

- Parsing standard EDA files (schematic, layout, parts list) automatically

- Using embedded libraries (part, package, materials, solder, laminate)

- Building box-level finite element analysis models

Analysis

Sherlock produces a holistic analysis that is critical to developing reliable electronics products. It enables designers to simulate each environment, failure mechanism and assembly that a product might encounter over its lifespan.

Assessment options include:

- Thermal cycling

- Mechanical shock

- Natural frequency

- Harmonic vibration

- Random vibration

- Bending

- Integrated circuit/semiconductor wearout

- Thermal derating

- Conductive anodic filament (CAF) qualification

- High-fidelity PCB modeling

Reporting & Recommendations

- Life curve

- Red-yellow-green risk indicators

- Tabular display

- Graphical overlay

- Binned results based on reliability goals

- Automated report generation

- Locked IP model for review by suppliers/customers

An Introduction to Ansys Sherlock

How Ansys Sherlock Simulations Optimise Electronic Hardware Design

How ANSYS Sherlock Simulations Optimize Electronic Hardware Design from Wilde Analysis on Vimeo.

Application of Software

Leveraging Physics of Failure

Physics of Failure (PoF), or Reliability Physics, uses degradation algorithms that describe how physical, chemical, mechanical, thermal or electrical mechanisms can decline over time and eventually induce failure. The specific term arose from an attempt to better predict the reliability of early-generation electronic parts and systems; however, the concept of PoF is common in many structural fields.

Utilizing PoF and Reliability Physics, Sherlock can accurately predict the failure behavior of next-generation components, including:

- Silicon transistors

- Wire bonds

- Solder bumps

- Die attach

- Light-emitting diodes

- Electrolytic capacitors

- Plated through-holes

- Solder joints

Accelerating Design Analytics

Electrical and mechanical engineers can work in tandem using Sherlock to Design for Reliability from the start of the project. Teams can use Sherlock to integrate design rules, best practices and Physics of Failure (PoF) methods, including

- 3D models of electronic assemblies for early analysis

- Trace modeling

- Post-processing of finite element simulations to identify critical components and predict time to failure

- Reliability predictions not previously possible

Sherlock also accelerates traditional design for reliability activities, including:

- Design Failure Mode and Effects Analysis (DFMEA)

- Thermal derating

- PCB Modeling and Simulation:

- Stackup: Sherlock allows for accurate selection of glass and fiber, informing the overall material properties selection.

- High Fidelity PCBs: Sherlock identifies mesh copper features within PCB substrate materials to identify potential risks.

- PCB Meshing: Sherlock identifies homogeneous mechanical properties of the uniform (whole) model and those of each layer in a layered model.

- Lead Modeling: Sherlock enables the addition of through-hole leads to select components and the viewing of virtually constructed PCBs in 3D.

- PCB Modeling and Simulation:

- Automatic ECAD data import, generation of 3D models and assignment of properties to 3D objects

- Simultaneous application of multiple environmental influences to test within specific parameters

- Automatic adjustment for materials, stackups and lifecycle events (thermal, shock and vibration)

- FEA calculations analysis for reliability predictions for all parts using validated models

- Near real-time production of custom reports (up to 100+ pages per PCB), plus dataset and image export capabilities

Sherlock automates the process, reduces required resources and provides results quicker. Design rework is accomplished within minutes, not weeks or months.

Reduce Manufacturing Risk

To maximize Design for Manufacturability (DfM) and Design for Reliability (DfR) in order to mitigate risk, Sherlock evaluates key components, including:

- Solder joint reliability to assure a product will function under given conditions, for a specified time, without exceeding defined failure levels

- Plated through-hole fatigue by using computerized modeling and temperature maps instead of human interfaces for accurate finite element test results

- Strain measurement during shock and vibration testing to gather data for prediction of failure probability, root causes of failure and failure events

- Material selection to align a plastic’s properties with design and functionality requirements

- Supplier analysis for building partnerships that can consistently deliver quality products and services without interruption

- Post-assembly handling operations assessment to identify areas for efficiency improvement after production

- Semiconductor wear-out, which allows manufacturers to evaluate and predict IC failures using an approach that follows SAE ARP 6338

Sherlock reduces the number of required physical testing iterations and improves the chances that prototypes will pass qualification tests in the first round. Engineers can design reliability right into electronics, allowing them to:

- Build and test virtual products

- Modify designs in near real-time

- Quickly run mechanical simulations

- Identify testing opportunities

- Evaluate design choices

- Gain project-specific insights

- Align reliability goals with metrics and requirements

Using Sherlock as part of your test plan significantly reduces the time and expense of multiple iterations of each qualification test, including:

Temperature Cycling

Instead of applying and working within the parameters of traditional methods, Sherlock designs the board and applies the temperature cycle to it. Faulty components and the number and type of failures are identified with certainty, allowing for a quicker, usually less costly fix to happen earlier in the process.

Plated Through-Hole Fatigue

Instead of allowing for human interfaces when monitoring several key contributors to PCB functionality, Sherlock’s computerized modeling is based on the temperature map from the solder fatigue input, and uses board stackup to calculate barrel stress for finite test results and remedy.

Vibration and Shock

The conventional probabilistic approach to vibration and shock testing cannot pinpoint actual failure events. Sherlock calculates board strain during mechanical shock and vibration testing, and then uses the data to predict the probability of failure and determine root causes of failure and corresponding failure events.

Conductive Anodic Filament (CAF)

Sherlock gathers data on drill hole locations and diameters directly from the computerized drill files, filters them by hole size and precisely identifies a “damage zone” between a pair of holes for focused analysis. This automated CAF qualification decreases the number of failures and ensures product reliability throughout manufacturing.

Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS)

HALT and HASS are excellent tools for design verification in the electronics industry. HALT provides insight into margins and weak points in design, and HASS is developed by running a combined temperature cycling/vibration HALT to failure and reducing the duration by 95%. This should ensure that only 5% of the life is consumed in HASS; however, it could be beneficial to confirm this assumption through a Sherlock Physics of Failure simulation. Sherlock also allows test/validation engineers to vary aspects of the HASS profile and understand their influence on life consumed.

Faster Testing