Risk analysis, maintenance strategy determination and asset criticality

ReliaSoft RCM++ software facilitates the reliability centered maintenance (RCM) analysis approach to improve reliability of the assets and optimize maintenance planning. The software supports all the major RCM industry standards, such as ATA MSG-3, SAE JA1011 and SAE JA1012 and provides full-featured capabilities for FMEAs and related analyses.

Discover key RCM++ capabilities for upstreaming the maintenance strategy

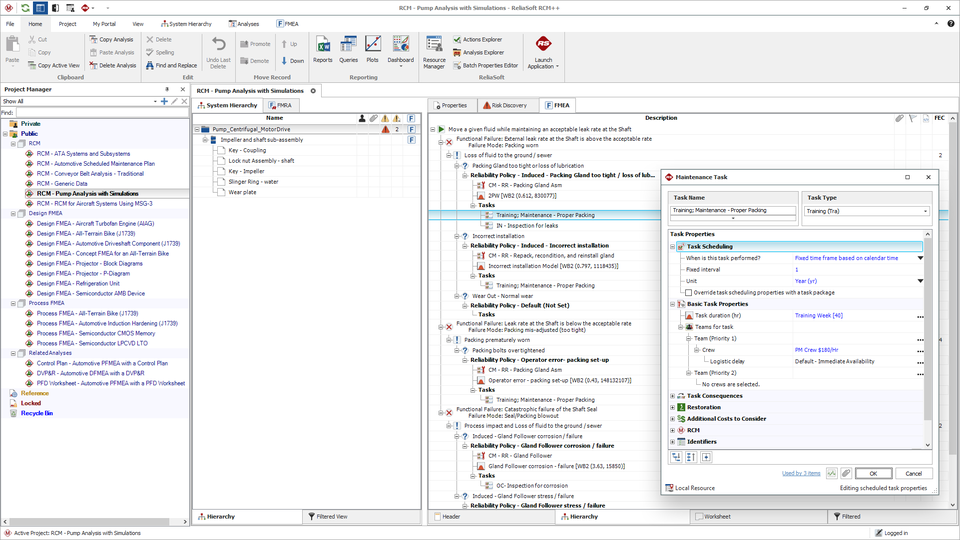

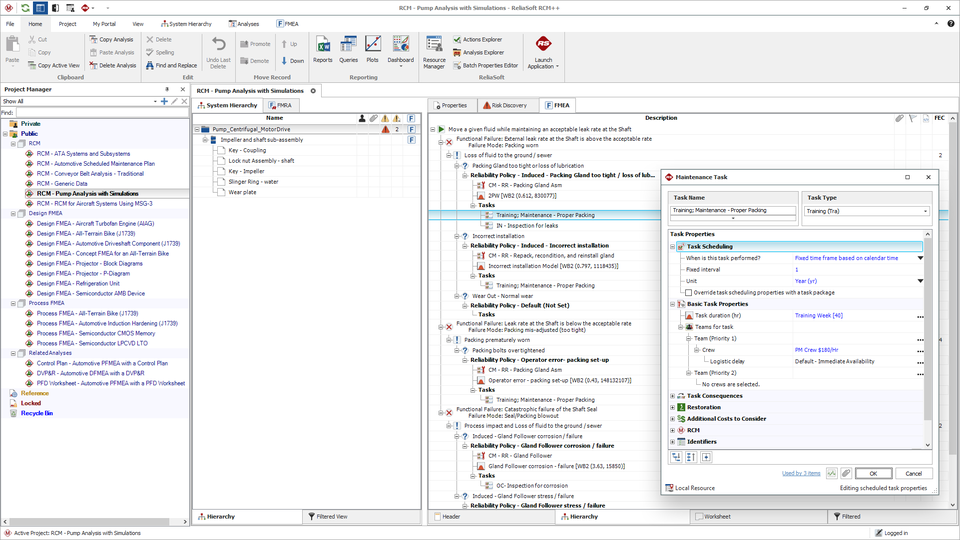

Optimise maintenance plans

Save time and money by designing processes based on criticality and consequences. Easily create maintenance tasks by configuring equipment and categorizing failure effects.

Assess risks at different levels using FMEA analysis

Perform FMEA and related analyses within your RCM analyses or independently.

Save time on data entry and analysis processes

Learn from past analyses to drive more efficient and more effective analyses.

Find cost-effective maintenance strategies

Compare the costs of potential maintenance strategies and estimate the optimum maintenance interval for preventive repairs/replacements with simulation-based calculations.

Minimise downtime and operating costs

Determine the optimal preventive maintenance (PM) program to proactively deter equipment failures.

Meet your organisation's specific needs

Easily configure your analysis workspace with predefined profiles to fit the major RCM and FMEA reporting standards.

See all functionality

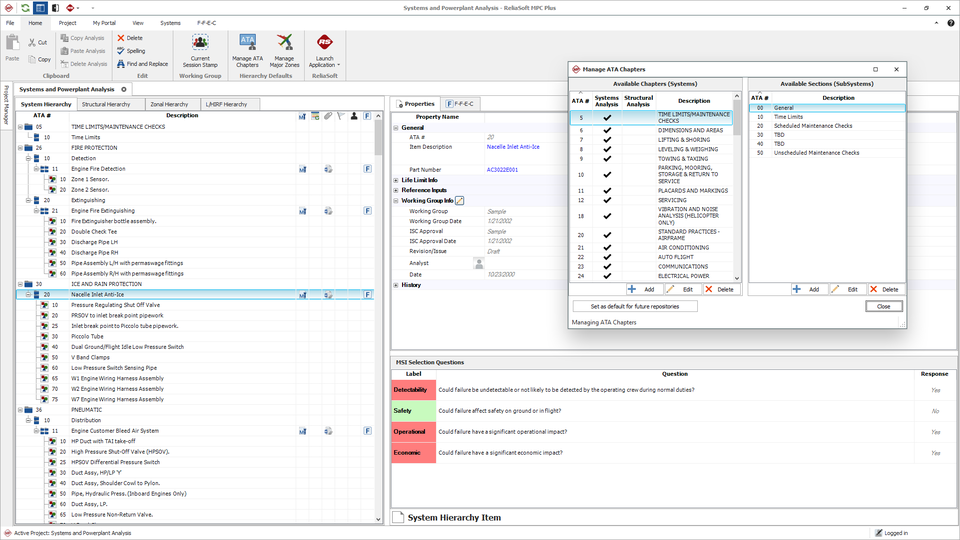

RCM standards

RCM++ provides predefined profiles that make it easy to configure the analysis workspace to fit the major RCM and FMEA reporting standards, such as:

- SAE JA1011/1012 for RCM

- MSG-3

- NAVAIR 00-25-403

In addition, the software offers flexible capabilities to customize any of the sample profiles or create your own settings to meet the specific needs of your organization.

Reliability Centered Maintenance (RCM) analysis

Equipment selection

In order to focus resources where they can provide the greatest benefit, the Risk Discovery Analysis feature provides a choice of two configurable methods to determine which equipment will be analyzed with RCM techniques.

Functional failure analysis

The Analysis panel makes it easy to switch back and forth between three complementary views of the functional failure analysis information so you can choose the display that is best suited for your current activity.

- The FMEA Hierarchy displays a lot of information in a compact space, where you can choose to display and enter causes before effects, if desired.

- The Worksheet View allows you to type directly in the worksheet cells and tab through the analysis as you would in a spreadsheet application such as Microsoft Excel.

- The Filtered View allows you to generate sortable lists of records of a type. For example, you may wish to see maintenance task records sorted by type, assigned interval, duration or cost.

Failure effect categorization and maintenance task selection

RCM++ supports the failure effect categorization (FEC) and maintenance task selection logic charts in the major industry RCM standards. You also have the option to customize the questions, categories and task types to fit your own specific analysis procedures.These configurable logic diagrams can help guide the analysis team to discuss the consequences of potential failure modes and consider the maintenance strategy that will be most applicable and effective.

Task packaging

It is easy to group individual tasks into packages based on factors such as time (scheduled interval), task type and areas in the system where tasks are performed. You can manually assign a task to the appropriate maintenance package or allow the software to automatically group tasks based on the criteria that you have specified for each package.

Maintenance strategies

Maintenance strategies based on cost and availability

Even when you choose to use the predefined decision logic diagrams employed by traditional RCM methods, those guidelines still require the analysis team to utilize their knowledge of the equipment's failure behavior when making decisions about the appropriate maintenance strategy. The built-in simulation and calculation engines help with these assessments.

Variety of statistical distributions to describe the failure behavior

RCM++ allows you to more accurately describe the probability of failure by providing a choice of ten distributions. Integration with Weibull++, and BlockSim software makes it possible to obtain the failure time distribution and parameters from an existing data analysis or RBD/fault tree. The software also provides the Quick Parameter Estimator (QPE) utility to help you estimate the distribution parameters based on limited information.

Maintenance strategies evaluation based on system availability at lowest cost

RCM++ makes it possible to simulate the operation of the equipment with different potential maintenance strategies in order to estimate the expected failures for each scenario and calculate the Average Availability, Cost per Uptime and Total Operating Cost.

Failure Modes and Reliability Analysis (FMRA)

Failure modes and reliability analysis (FMRA) feature helps you to integrate statistical reliability analysis calculations into your FMEA and RCM activities. It can be used to:

- Display the FMEA records that could have an impact on system reliability/maintainability to define the relevant reliability characteristics.

- Calculate the probabilities of failure required for a quantitative criticality analysis.

- Use the occurrence ratings to generate a preliminary baseline reliability estimate.

- Synchronize with BlockSim’s reliability block diagrams (RBDs) or fault trees.

- Allocate the target reliability and target availability.

Optimum replacement interval

Automatically calculate the optimum replacement interval that will minimize corrective and preventive maintenance costs. You can calculate the optimum time for an individual item, or to calculate a time that will be optimum for a specified group of items.

FMEAs and related analyses

RCM++ provides a complete set of features for FMEA and related analyses, which can be used independently or integrated with any RCM analysis. For example, you may wish to use RCM for some equipment and FMEA for other equipment, depending on the assessed criticality. Alternatively, you may wish to incorporate the Risk Priority Number (RPN) method as an additional risk assessment tool in some of your RCM analyses. The software also provides configurable utilities for:

- Design Verification Plans and Reports (DVP&Rs)

- Process Flow Diagrams (PFDs)

- Process Control Plans (PCPs)

- Design Reviews Based on Failure Mode (DRBFMs)

- P-Diagrams

Queries, reports, charts and diagrams

The software provides a complete range of options for presenting the data in ways that will effectively communicate results and facilitate decision-making:

- Queries and print-ready reports to manage predefined and customized templates that can be made available to all database users, applied to any data set and incorporated into any print-ready report document.

- The Query Utility window is a powerful analysis tool that makes it easy to find and open specific sections of the analysis. It is also a flexible custom reporting tool that allows you to create and manage saved queries.

- The Reports window makes it easy to build report documents that include the predefined report forms, custom report forms and/or custom queries that will be most effective to present your analysis results. Since you can generate these documents directly in Microsoft Word or Excel, it is easy to customize and distribute reports without a specialized report editor or viewer.

If your organization chooses to implement a SEP web portal for an enterprise database, you can also publish these reports to the portal (in Word, Excel, PDF or MHTML format), where they can be accessed from any web-enabled device.

- The Plot Viewer provides an array of flexible options to create attractive bar charts, pie charts and matrix charts based on the analysis data. The software also generates Cause and Effect Diagrams and Failure Relationship Diagrams to help you visualize the relationships between issues in your analyses.

- FMEA/FMRA dashboards, where you can create customized dashboards to present data from FMEA and FMRA analyses in XFMEA/RCM++/RBI. In addition, if your organization chooses to implement a web-based portal for an enterprise database, you can now share selected dashboards to be accessed from any web-enabled device.

Data management tools and utilities

The software provides an array of tools to help you find and reuse descriptions from any existing analysis and to select phrases from predefined templates or phrase libraries. You also can use fully customizable Excel® templates to quickly import system configurations and/or analysis data from external data sources. You have an ability to import system configuration data from XFMEA, RBI, MPC and XFRACAS as well.

FRACAS integration

You can automatically import system configuration data from an external Bill of Materials file or from XFRACAS (web-based FRACAS software). For an enterprise database, you can maintain a direct link to the XFRACAS system, which makes it easy to resynchronize at any time. This connection also enables the FMEA team to tap into valuable information about failure modes that are observed during testing and in the field, including incident quantities and new failure modes that may not have been considered yet.

Learn more about industry specific versions of RCM++

Support the MSG-3 process for aircraft systems and powerplant analysis

ReliaSoft MPC is an MSG-3 compliant maintenance program creator for the aircraft/aerospace industry with flexible data management capabilities and automated report.

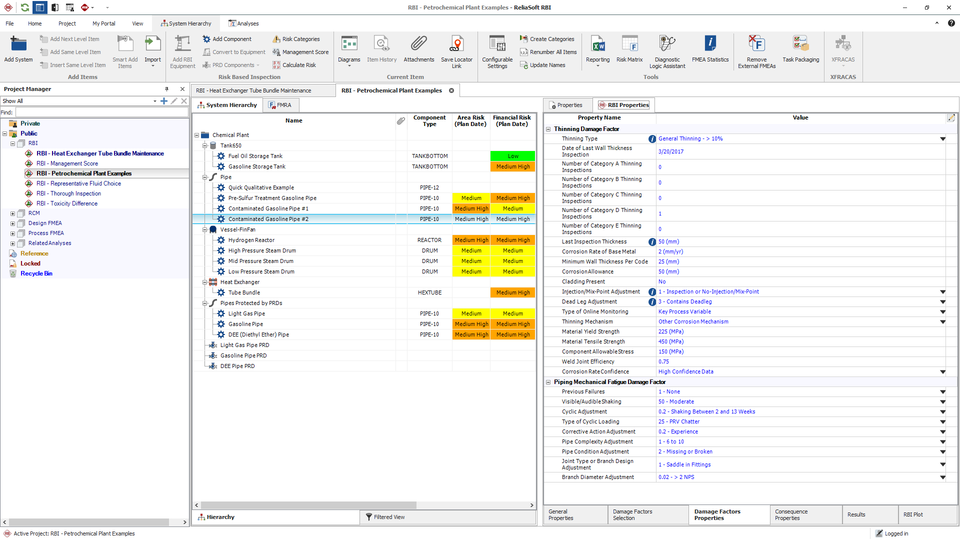

Predict the high risks of the assets to improve safety and reduce the costs

ReliaSoft RBI software facilitates risk based inspection (RBI) analysis for Oil & Gas, chemical and power plants according to the API RP 581 Rev 3 (2016) and the ASME PCC-3-2007 publications.